At OHC, we take pride in providing the very best quality hardwoods. Our high standard is what drives us to pay close attention to the details in every step of our process.

We’ve developed a specialized method over the years to machine and mill our hardwood. This process allows us to create custom hardwood products that other manufacturers simply cannot.

Let’s take a look at how we do this:

Carbide —the obvious choice for cutting hardwood

For softwoods like pine and poplar (along with cheaper hardwoods), a high-speed steel (HSS) knife is generally used.

However, we cut all of our wood with a carbide knife. This is a much harder and more durable material that is able to cut into the densest of hardwoods and create the most professional machined finish. Diamond tipped sharpening equipment is required to maintain carbide blades.

While carbide blades are more expensive, it is able to machine the hardest hardwoods and stay sharp for much longer than HSS.

Now, let’s get to the angle of attack

When cutting lumber the angle of cut is anywhere from 9-24 degrees. The higher the degree, the faster the blade dulls, but the finer the finish. While you will typically use a 22-24 degree angle with an HSS steel blade, a carbide blade will cut at 9-22 degrees.

What’s the difference?

The larger the angle, the deeper and cleaner the cut will be. However, the blade will dull much quicker. When there is a broader point, the blade is able to stay sharper longer (which is a huge benefit when cutting hardwood).

We’ve accumulated years of experience in order to determine what angle we should use based on the type of wood we are cutting (we use 22-, 14-, and 9-degree angles, depending on what we are cutting).

To us — it’s personal

One of the things we’re most proud of at OHC is our ability to mill custom orders for the projects that our clients dream up. This is because we have the capability to make our own cutters.

First, we take the carbide blank into our grinding room and grind it to the profile our customer needs — depending on what the engineer or architect dreams up.

The body is then made to match the profile and we braise our own carbide onto that. The dedicated knife can only run that one profile, but it can run a great amount of footage without needing frequent sharpening.

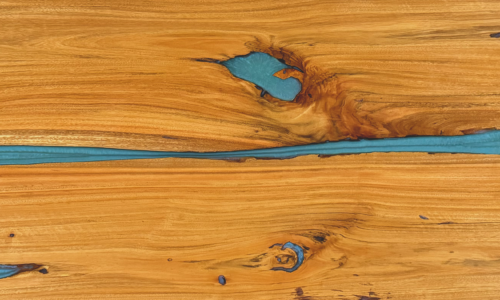

Here are some examples of highly customized profiles that we’ve cut for our clients:

For this project, we ran around 40,000 feet of this unique profile (all in-house). We created a custom cutter to create anti-slip boards for the visitors of the Houston Zoo.

Because of our ability to run a custom knife profile for every project, we are able to tackle virtually any project including siding, soffits, and truck trailer flooring.

Another way that we’re able to create such personalized hardwood products is our ability to run veneers with our frame saw. We are able to to take dense hardwoods, such as Burmese Teak and Ipe, and run them into as small as 2.7 mm veneers.

Overall, we go through such an extensive and personalized process to mill and machine our hardwood because we want to offer the very best products.

We’d love to talk to you more about how we mill and machine our hardwood. Contact us here.